NVIDIA recently announced a partnership with TSMC to produce next-generation CPUs and GPUs, leading to a continuous surge in demand for AI chips. As line widths shrink, every single lithography exposure determines yield and competitive edge.

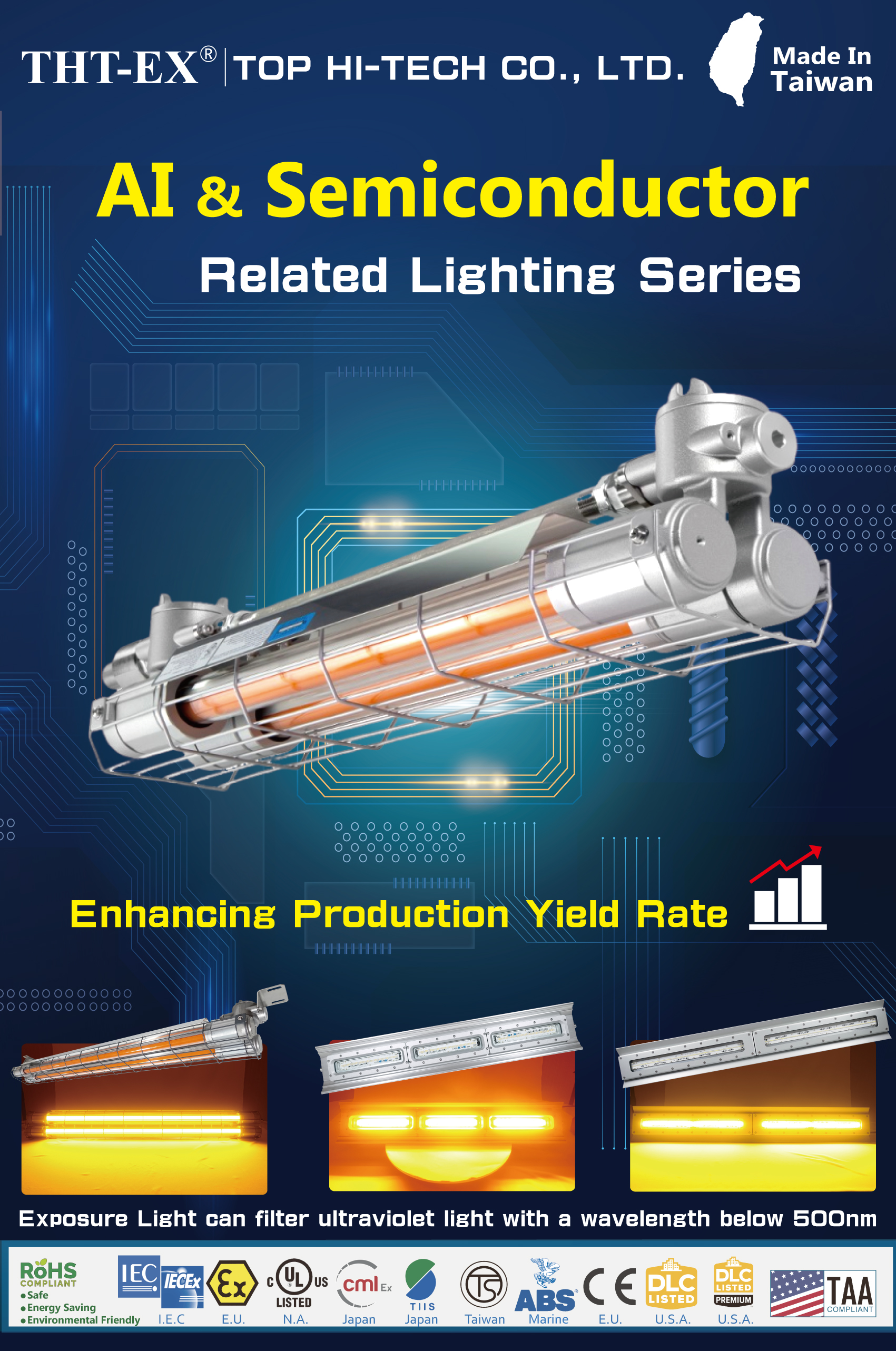

In this AI revolution, THT-EX's 500nm yellow lighting is the invisible cornerstone of semiconductor cleanrooms:

●Prevents unwanted photochemical reactions, ensuring line width precision.

●ISO 14644 cleanroom compliant, with a zero-contamination design.

●24/7 high reliability, supporting the most demanding processes.

●Already in use at leading global AI and semiconductor factories.

NVIDIA is driving an AI infrastructure revolution, from Blackwell and Rubin CPX to high-density GPU hosting in data centers. Chip line widths are getting smaller, and architectures are becoming more complex. Neglecting the importance of 500nm yellow lighting during the exposure/lithography process can not only cause a drop in yield but also lead to a loss of competitive advantage.

In this wave of AI, we don't just illuminate the future; we protect every nanometer of the production line.

THT-EX 500nm Precision Exposure Lighting — Illuminating the purest light for chip manufacturing in the age of AI.

●Online Catalog: https://drive.google.com/file/d/1HHGMZNkb-n2SZBgNJj1vCW1jGqLEFcqY/view?usp=drive_link

●YouTube:https://lnkd.in/fxjEDNF

●E-mail:sales@tht-ex.com

#Semiconductor #AI #NVIDIA #Cleanroom #Photolithography #THTEX